Ceiling heating and cooling

For a comfortable room climate all year round

In buildings with increasingly better thermal insulation and a large proportion of glass surfaces, unwelcome increases in internal temperatures can occur on sunny days. It is recommended to use ceiling and wall elements for heating and cooling purposes to create a comfortable indoor climate, especially in the summer months. The systems can be used individually or together with a surface heating system. The combination with heat pump systems enables efficient temperature control of individual rooms or entire buildings.

The EMPUR® product range now includes two variations of a ceiling heating/cooling system. On the one hand, aluminium ceiling elements for heating and cooling for suspended ceiling grids and, on the other hand, ceiling and wall elements made with a special plasterboard.

Suspended ceilings have been the standard in modern office, commercial and administrative buildings for a long time. They look good, provide sound insulation and make large parts of the extensive building services invisible to visitors of the building. These drywall ceilings can also be used to air-condition the rooms. The EMPUR® ceiling heating and cooling system is simply inserted into the existing metal rail construction.

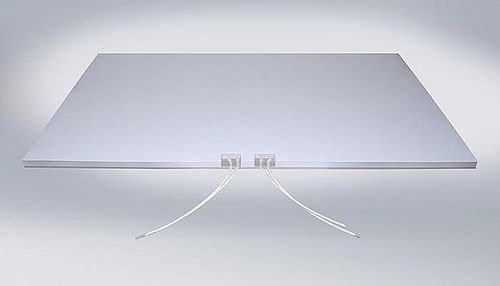

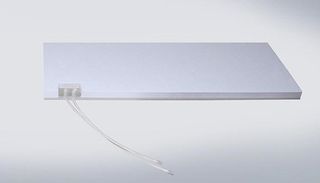

The new, ready-to-use ceiling and wall element for heating and cooling by EMPUR® is made with a special plasterboard with insulation on the back. In just a few steps, the EMPUR® system elements are used to create a drywall ceiling or a drywall that can efficiently control the temperature of the respective room. The element is ideal for renovation projects in which the floor cannot or only partially be used for surface heating, as well as for all new-build projects.

Ceiling element in use in suspended drywall ceilings

Ceiling element in use in suspended drywall ceilings Ceiling heating system element made with plasterboard

Ceiling heating system element made with plasterboardAluminium ceiling elements

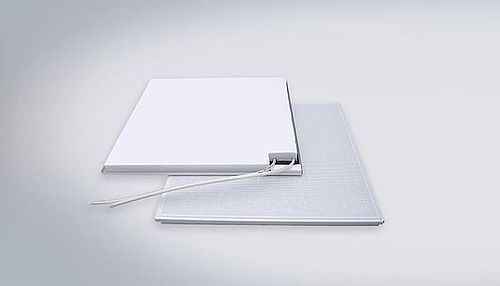

The ceiling heating and cooling system is designed for drywalls in new-builds or renovation projects. The ceiling elements consist of a powder-coated aluminium sheet. On the back, the elements are covered with 30 mm EPS thermal insulation (WLS 035) into which the high-quality PE-RT 5-layer pipe is integrated at the factory. The low weight enables simple and straightforward handling. The 600x600 grid size prefabricated with a heating circuit – alternatively without a pipe circuit as a dummy/compensating element – allows for flexible design of the ceiling surface. The ceiling elements can be installed in combination with standard ceiling substructures (e.g. T 24 support rail systems). Special plug-in couplings connect the elements. Aluminium ceiling elements for system ceiling grids

Aluminium ceiling elements for system ceiling gridsThe benefits of EMPUR® aluminium ceiling elements

- Easy installation in new or existing suspended system ceiling grids

- Low-maintenance and durable surface thanks to powder coating

- Suitable for cooling and heating

- Low thermal inertia, with good adjustment

- Low weight, fast installation on standard ceiling substructures

- High performance with low system temperatures

- Noiseless, even and practically draft-free temperature distribution

Plasterboard ceiling elements

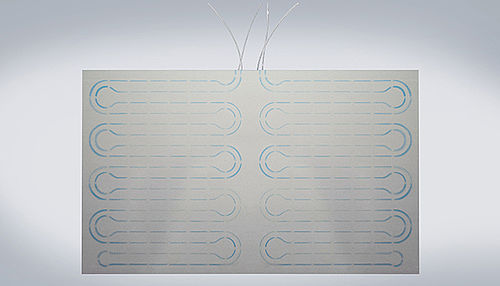

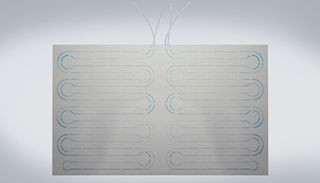

The drywall elements consist of a 12.5 mm thick plasterboard into which the high-quality PE-RT 5-layer pipe is integrated at the factory. On the back, the elements are covered with 30 mm EPS thermal insulation (WLS 035). The total board thickness of 42.5 mm ensures both sufficient and lightweight board stability. The position of the heating pipes is clearly printed on the surface of the panels to facilitate installation. Two prefabricated panel sizes with one or two heating circuits enable flexible design of the ceiling and wall surfaces. Another element, without a pipe circuit, can be used as a compensating/dummy element. The elements can be processed with standard profiles (e.g. CD 60/27/06), such as a standard plasterboard. The wall and ceiling heating and cooling system is designed for drywalls in new-builds or renovation projects. Plasterboard ceiling elements for wall and ceiling installation

Plasterboard ceiling elements for wall and ceiling installationThe benefits of EMPUR® plasterboard ceiling/wall elements

- Ready-to-use drywall element

- Installation possible on wall and ceiling

- Suitable for cooling and heating

- Fast response, low thermal inertia

- Easy and quick installation on standard drywall profiles

- Top-side insulation significantly reduces heat loss

- High level of living comfort with low system temperatures

- Surface can be painted and covered with wallpaper

ATTENTION: EMPUR® ceiling heating elements must be measured by the specialist planner and may only be installed and commissioned by authorised specialist companies. Installation and assembly must be carried out in accordance with the applicable technical rules and the latest technology. The specifications of the manufacturers of the rail system elements or the profile systems must also be taken into account and observed.

-

Detailed photos

Detailed photos

Easy installation of grid elements

Easy installation of grid elements Low-maintenance and durable powder coating

Low-maintenance and durable powder coating Ceiling element H/C aluminium 600x600x30 mm

Ceiling element H/C aluminium 600x600x30 mm Aluminium ceiling compensation element without

Aluminium ceiling compensation element without

function Plasterboard 2,000x1,200x42.5 mm

Plasterboard 2,000x1,200x42.5 mm Visible position of heating pipes

Visible position of heating pipes Plasterboard 1,200x500x42.5 mm

Plasterboard 1,200x500x42.5 mm Compensation element without function

Compensation element without function Through fitting with 2 outlets

Through fitting with 2 outlets Through fitting with 4 outlets

Through fitting with 4 outlets Plug for push fitting

Plug for push fitting Coupling

Coupling -

Benefits for the processor

Benefits for the processor

Aluminium ceiling element

- Easiest installation in new or existing suspended system ceiling grids

- Low-maintenance and durable surface thanks to powder coating

- Quick response times, allowing for adjustment

- Noiseless, even and practically draft-free temperature distribution

- Energy savings through low flow temperatures

- Low surface area weight for the renovation of old buildings

- Fast installation on standard ceiling substructures and quick construction process

Plasterboard ceiling/wall elements

- Wall or ceiling installation possible

- Quick response times, allowing for adjustment

- Easy and quick installation on standard drywall profiles

- Thermal insulation significantly surpasses similarly heated rooms (DIN EN 1264, R> = 0.75 m2 K / W)

Both systems

- Many expansion possibilities - comprehensive EMPUR® range with various system accessories and tools, as well as manifold and control technology products

- Can be combined with a floor heating system

- Easily connected to existing heating systems

- 10-year material and consequential damage liability on EMPUR® heating pipe with exclusive use of our system components under adherence to further warranty conditions (see EMPUR® warranty certificate)

-

Benefits for the end-consumer

Benefits for the end-consumer

Aluminium ceiling element

- Low-maintenance and durable surface thanks to powder coating

- Quick response times, allowing for adjustment

- Noiseless, even and practically draft-free temperature distribution

- Energy savings through low flow temperatures

- Low surface area weight for the renovation of old buildings

- Fast installation on standard ceiling substructures and quick construction process

Plasterboard ceiling/wall elements

- Wall or ceiling installation possible

- Quick response times, allowing for adjustment

- Easy and quick installation on standard drywall profiles

- Thermal insulation significantly surpasses similarly heated rooms (DIN EN 1264, R> = 0.75 m2 K / W)

Both systems

- No restriction of modernisation possibilities

- Increases building value

- High level of living comfort with low system temperatures

- Many expansion possibilities - comprehensive EMPUR® range with various system accessories and tools, as well as manifold and control technology products

- Can be combined with a floor heating system

- Easily connected to existing heating systems

- 10-year material and consequential damage liability on EMPUR® heating pipe with exclusive use of our system components under adherence to further warranty conditions (see EMPUR® warranty certificate)

We are happy to answer any questions you might have regarding our system ceiling heating/cooling!

You can find further current sales or technical product documents as PDF for download HERE.

The respective departments in our plants are always at your disposal if you require advice. Or simply use our contact form!