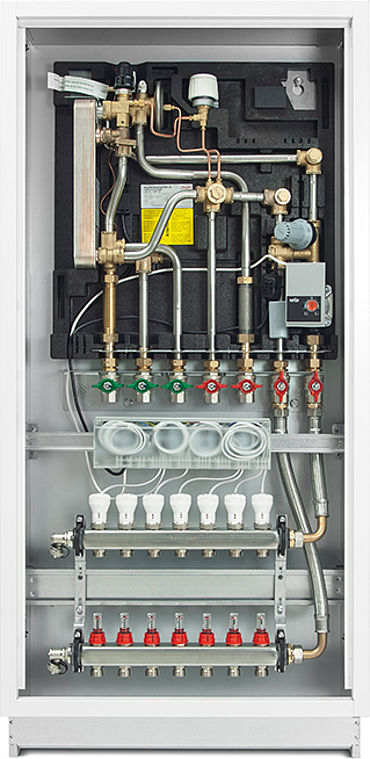

Flat transfer stations

System solutions for heat distribution and hygienic tap water

Energy efficiency is a high priority for builders, whether for new build or renovation. Reducing energy requirements and compliance with statutory regulations are matters of far-reaching importance. Decentralized heating systems reduce heat losses and heating costs, while also increasing comfort and the hygiene of tap water.

Tenants and property owners both want maximum comfort from their heating system at the lowest possible cost. They are less concerned at first about the source of energy used or how the system works.

A flat transfer station regulates the amount of heat supplied for space and water heating to each apartment of a multi-apartment block. These stations can be used in new build but can also be employed in the modernisation of older buildings.

Flat transfer stations for direct, decentralised heating operate on the heating side with no system separation. The primary energy carrier flows directly into the unit from the supply network. This is where the control components are employed to obtain the required temperature. Thus, the tap water is heated on a continuous flow basis and is only provided when it is actually required and used. Provided that they are carefully designed, planned and installed, these systems do not require regular legionella inspections as are prescribed for central hot water systems by the Ordinance on water for human consumption (Trinkwasserverordnung).

Decentralised continuous flow water heater

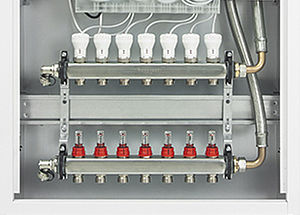

- Hydraulic unit for decentralised hot water supply

- For direct connection to an EMPUR® floor heating distributor with up to 12 heating circuits

- Can be used without further modifications if the pipeline volume connected to the station does not exceed 3 litres

- Central installation location in the dwelling, usually in the bathroom or corridor area, in compliance with Guideline 551 (the 3-litre rule) of the German gas and water association DVGW is recommended

- With built-in adapters for the incoming cold water meter and the heat flow meter to allow easy calculation for each unit

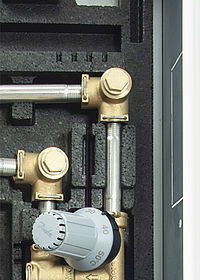

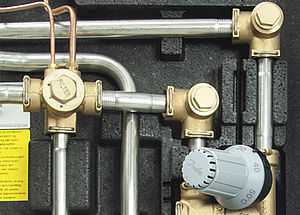

Dimpled heat exchanger

- Improved performance, reduced pressure loss and lower return temperatures compared to conventional plate heat exchangers

Combined controller for heating and hot water

- For a constant return temperature even in the partial load range

- Differential pressure regulator for hot water and heating

- With integral zone valve

- Hose connection for bleeding

Summer bypass

- Adjustable in range 20 – 50 °C

- Hot water with low energy loss

Heat insulation

- Rear wall insulation and insulated hood in standard version

- EPP insulation >=0.039 W/(m*K) for lowest heat loss with complete insulation (<150kWh/a)

Click-fit pipe joints

- No retightening means fast installation and lower construction costs

- No risk of leaks and thus no consequential costs

- Durable joint (tested to a pressure of 200 bar)

Connection point for high-temperature circuit (radiators)

- Insulated hood with cut-out and rated breaking point

- Cut-out in transfer box (pipework outside insulation on construction side)

Please note that the design and calculations for the stations are performed by our technical department using a planning tool and based on building-specific project data.

-

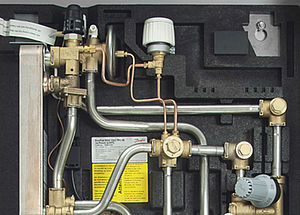

Detailed photos

Direct connection of a heating circuit manifold

Quick installation due to click-fit pipe connections

Mounting rail with 7 shut-off ball valves

Dimpled heat exchanger, combi-controller summer bypass

Decentralised flow-through drinking water heater

Full insulation through rear wall insulation and insulation cover

We are happy to answer any questions you might have regarding our flat transfer stations!

We are always at your disposal if you require advice. Or simply use our contact form!