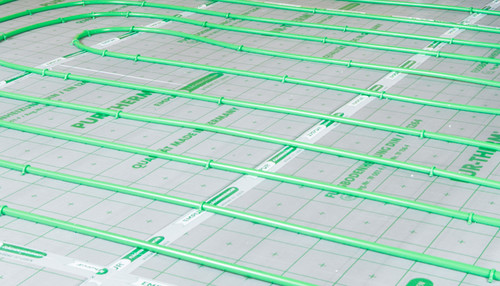

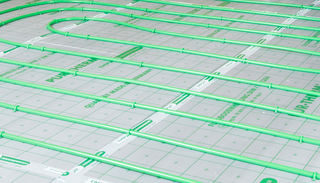

PUR-THERM® stapler system

The system solution for versatile installation heights

The EMPUR® PUR-THERM® stapler system is a proven and well-known floor heating system, consisting of PUR-THERM® composite panels, KLIMAPEX® plastic heating pipes and PUR-THERM® staples as its main components.

The PUR-THERM® composite panels with foamed, highly tear-resistant, multi-layer composite film ensure that the staples provide exceptional adhesion for the securing of the heating pipes. A predefined laying grid as well as a single-sided film overhang for overlapped laying makes stapling with the PUR-THERM® stapler system conceivably easy. To ensure good heat transfer, the heating pipe is uniformly covered with screed.

The stapler system components are all developed by EMPUR® and produced in-house in Germany.

The EMPUR® stapler system has many uses:

- in new and old buildings

- in residential and commercial buildings

- in single family houses and buildings for multiple families

- in industrial buildings, in public areas and sports facilities

The components of the market-renowned PUR-THERM® stapler system are optimally matched to each other.

The components of the market-renowned PUR-THERM® stapler system are optimally matched to each other.Take 2 minutes...

...and we will demonstrate the laying of our PUR-THERM® stapler system to you!

-

Detailed photos

Detailed photos

Turbo-Cube panels

Turbo-Cube panels Quick laying of composite panels

Quick laying of composite panels PUR-THERM® system tacker

PUR-THERM® system tacker Ergonomic working position

Ergonomic working position Laying as per predefined grid

Laying as per predefined grid Finished laying surface

Finished laying surface Connection to the brass manifold

Connection to the brass manifold -

Benefits for the processor

- One system, one manufacturer - from consultation to design and on to component delivery

- Security for end-clients and processors - system components optimally adapted to each other with universal licences

- Proven quality through in-house production

- Quick and neat processing of the system panels

- Robust panel during use with long-term stability

- Predefined laying grid (50 mm) as an orientation aid when positioning the KLIMAPEX® plastic heating pipes

- Low weight of material, enabling easy and non-tiring installation

- Turbo-Cube panels in versions with various insulation materials enable quick laying even in large rooms

- Easy laying - easy and quick laying out of the insulation materials, short installation times

- Easy handling of the few system components

- Single-sided film overhang for overlapped laying

- Minimal waste due to overlay technology

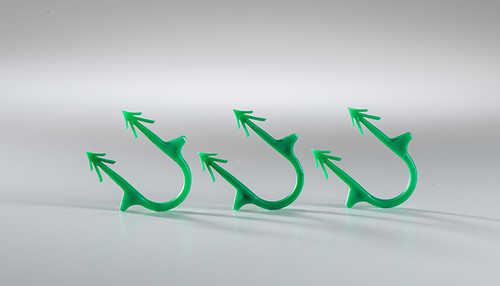

- Simple and secure installation of KLIMAPEX® plastic heating pipes with the staple system

- Laminated, highly tear-resistant fabric film, for exceptional staple adhesion and secure installation of the KLIMAPEX® plastic heating pipes

- Quick and flexible laying of pipes of all dimensions and qualities

- Many insulation materials available with various strengths

- Various system panels available with or without impact noise reduction

- Heat insulation across the entire surface

- Optimal combination with calcium sulphate liquid screeds thanks to the KLIMAPEX® plastic heating pipes being covered in their entirety

- The system tacker provides for an ergonomic working position and is easy to use. The low weight ensures non-tiresome working. Pre-loaded staples are lodged into the composite film safely and quickly.

- Many expansion possibilities - comprehensive EMPUR® range with additional insulation materials and various system accessories and tools, as well as manifold and control technology products

- Simple implementation of thermal insulation requirements in new and old buildings

- Well-known system with years of practical experience

- 10-year material and consequential damage liability on EMPUR® heating pipe with exclusive use of our system components under adherence to further warranty conditions (see EMPUR® warranty certificate)

-

Benefits for the end-consumer

- One system, one manufacturer - from consultation to design and on to component delivery

- Security for end-clients and processors - system components optimally adapted to each other with universal licences

- Proven quality through in-house production

- Minimal waste due to overlay technology

- Simple and secure installation of KLIMAPEX® plastic heating pipes with the staple system

- Laminated, highly tear-resistant fabric film film, for exceptional staple adhesion and secure installation of the KLIMAPEX® plastic heating pipes

- Many insulation materials available in various thicknesses

- Various system panels available with or without sound absoprtion

- Heat insulation across the entire surface

- Optimal combination with calcium sulphate liquid screeds thanks to the KLIMAPEX® plastic heating pipes being covered in their entirety

- Many expansion possibilities - comprehensive EMPUR® range with additional insulation materials and various system accessories and tools, as well as manifold and control technology products

- Simple implementation of thermal insulation requirements in new and old buildings

- Ideal for modern heat generators (condensing boilers, regenerative heat generators, etc.)

- No swirling up of dust, suitable for people with allergies

- Highest comfort thanks to heat radiation

- New design possibilities without heaters

- Increases building value

- Energy savings through low flow temperatures

- Floor heating for all layouts

- Comfort thanks to even heat distribution

- PUR panels with the highest heat insulation value for reduced installation height - forward-thinking heat insulation

- Well-known system with years of practical experience

- Energy efficiency - best energy footprint with PUR-THERM® products

- 10-year material and consequential damage liability on EMPUR® heating pipe with exclusive use of our system components under adherence to further warranty conditions (see EMPUR® warranty certificate)

We are happy to answer any questions you might have regarding our stapler system!

You can find further current sales or technical product documents as PDF for download HERE.

The respective departments in our plants are always at your disposal if you require advice. Or simply use our contact form!

Perfect hold

Perfect hold